- April 11, 2025

iPhone Manufactured in the USA: Is It Feasible and How Would It Impact Prices?

The market discussion surrounding the United States production of iPhones has intensified along with economic and political conditions that advocate for production relocation from overseas. The United States has steadily increased its demand for Apple to relocate its production operations within national borders. The manufacturing of iPhones in the USA proves challenging since we need to determine the resulting economic effects for both Apple and its customers. This blog examines the production expenses in the USA for iPhones together with Apple’s current difficulties and the requirements for China-to-America manufacturing relocation.

iPhone Manufactured in the USA: The Economic and Logistical Challenges

The US faces major challenges when considering iPhone manufacturing within its territory due to the high production expenses in the USA. Manufacturing labor costs are substantially higher in the United States than the labor expenses in China where Apple conducts its product assembly operations. Apple selected China because the local workforce operates at significantly lower rates when compared to American labor costs. Thus the country remains attractive to manufacturers who seek reduced production expenses. Apple needs to accept increased labor expense for U.S. production which would result in higher prices for their products.

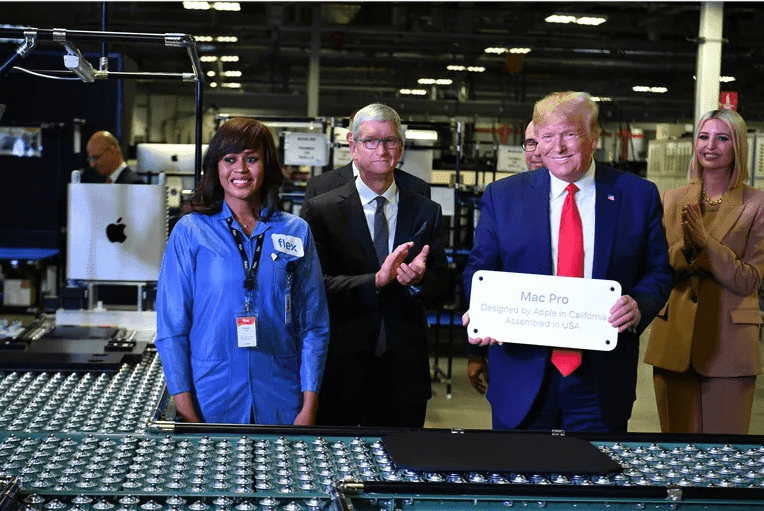

Apple production in the USA

The feasibility of Apple production in the USA faces challenges because the United States lacks the required facilities and infrastructure for large-scale electronics manufacturing. The construction of a production line inside the U.S. capable of assembling millions of iPhones annually would demand massive financial investment from Apple despite its manufacturing facilities in Texas and other parts of the country. Studies indicate the investment for this project would stretch over several years while the total expense runs into multiple billion-dollar amounts.

Domestic iPhone Assembly Challenges: A Long Road Ahead

Multiple issues block the domestic assembly of iPhones. The iPhone Manufactured in the USA production process requires global supply chains even though Apple has shown success in U.S. iPhone component assembly. The iPhone modules obtain their components through an international distribution network that frequently links China with Japan South Korea and other international countries. The U.S. manufacturing model would need total reconstruction to unite every single supplier located worldwide.

Labor needs for assembling iPhones in the USA represent a significant priority during production. The United States possesses expert workers however it lacks enough qualified personnel for specific production roles in electronics manufacturing. For Apple to transition its supply chain the company needs to create specialized training programs but such initiatives will need sustained time investment together with substantial resources. Apple would face additional expenses when training staff because there is little existing workforce preparedness for the move.

The Impact of Tariffs on iPhone Prices

The price effect of tariffs on iPhones Manufactured in the USA products stands as the core cause behind the domestic production movement for iPhones in the USA. The cost of iPhone production remains low for Apple because they operate out of China where tariff rates exceed those of American facilities. Apple would experience greater costs because bringing manufacturing operations back to U.S. soil would lead to elevated duties and taxes for imported materials. The rising manufacturing expenses would unavoidably drive up iPhone production prices for retail markets.

USA and China regarding iPhone

The dispute between the USA and China regarding iPhone production gets even more complex due to their ongoing trade conflicts. The expansion of Apple’s supply chain network to more countries makes manufacturers evaluate new options for their production locations. US-based iPhone manufacturing would bring economic benefits which will vary based on labor expenses and trade protocol satisfaction as well as the entire production network performance.

Technological Infrastructure for iPhone Assembly in the USA

Attention must be paid to the technological framework used for assembling iPhones in the United States. Manufacturing technology at the highest level must exist for Apple to produce iPhones efficiently. Pure production of iPhones in the USA needs substantial funding for advanced machinery and robots alongside many specialized manufacturing tools. At present Apple cooperates with Chinese producers such as Foxconn to execute these assembly steps. Apple needs to establish domestic production of this technology or work with U.S. suppliers who possess the necessary production equipment.

The transition plans to enhance United States facilities to undertake precise iPhone manufacturing techniques. The manufacturing procedure for Apple must carry out assembly and testing operations with maximum efficiency while also saving costs at every manufacturing stage.

The Future of iPhone Manufacturing in America: What Lies Ahead?

Future prospects regarding iPhone Manufactured in the USA production located in America remain without clarity. Apple achieved supply chain expansion through its investments in factory facilities across India and Vietnam. The extensive relocation of complete iPhone Manufactured in the USA operations to the United States faces major challenges despite efforts made by the company. Apple may transfer parts of its production to the United States but will most likely continue using overseas facilities throughout the immediate future.

Apple depends heavily on Chinese manufacturing capabilities to sustain its worldwide supply network operations. Apple faces significant obstacles while making the transformative supply chain shift from China to the American nation. The U.S.-based iPhone production will not stop Apple from sustaining its international supplier network to keep operations efficient and affordable.

The following essential considerations exist regarding the US production of iPhone devices.

- The manufacturing switch from China to the United States would cause production expenses to rise because both domestic labor prices and foreign component tariffs would increase.

- Finding domestic suppliers for components requires Apple to transform its worldwide supply chain and bring production operations into the U.S.

- iPhone production USA demands specific workers who require training from Apple to achieve consumer demand.

- Constructing or upgrading facilities in the United States that meet Chinese technical standards for iPhone production requires substantial financing.

- The introduction of iPhone production facilities within the United States would create extensive economic effects that touch both the workforce dynamics and the development of the technology sector.

- Tariffs along with trade wars between the USA and China will determine how Apple makes future domestic production choices for iPhones.

Conclusion

The goal of producing iPhones in the United States presents numerous difficulties despite its promising concept. Apple must dedicate substantial resources and delay production start dates for domestic iPhone manufacturing because both the production expenses and necessary development of assembly technology are high. Domestic iPhone Manufactured in the USA . faces an unclear future despite the existing logistical barriers and economic difficulties along the path toward home-based iPhone creation. The future of total American iPhone production by Apple remains uncertain yet such a move would significantly transform the USA-Chinese iPhone Manufactured in the USA dynamics for multiple years.